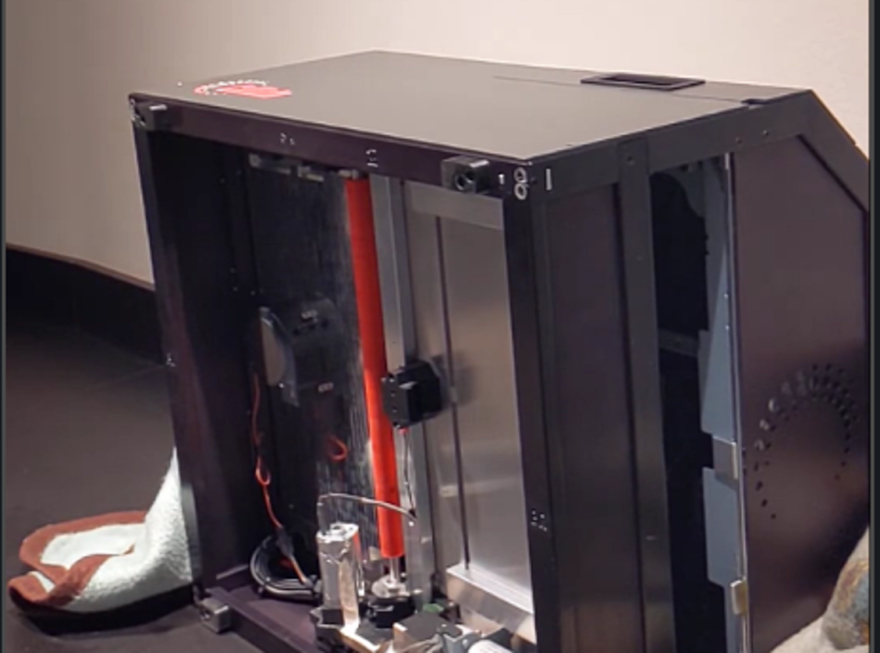

The Callisto printer has a main drive roller or set of rollers that go across the width of the print track to move the media. These polyurethane rollers are orange in color and somewhat rubbery to the touch. Because the drive rollers touch the media, they can collect dust, glue, ink, and other media-related debris.

The drive rollers are easily cleaned with the following procedure. The video shows how to set the printer on its back so the rollers can be accessed for cleaning, and it demonstrates how to clean the rollers.

First, prepare the printer for cleaning by doing the following.

- Remove any media from the printer.

- Turn the printer off with the front power button.

- When the printer is completely shut down, turn the back power switch to the OFF position.

- Remove the power and network cables from the back of the printer.

- Remove any peripherals, such as a stacking tray, attached to the printer.

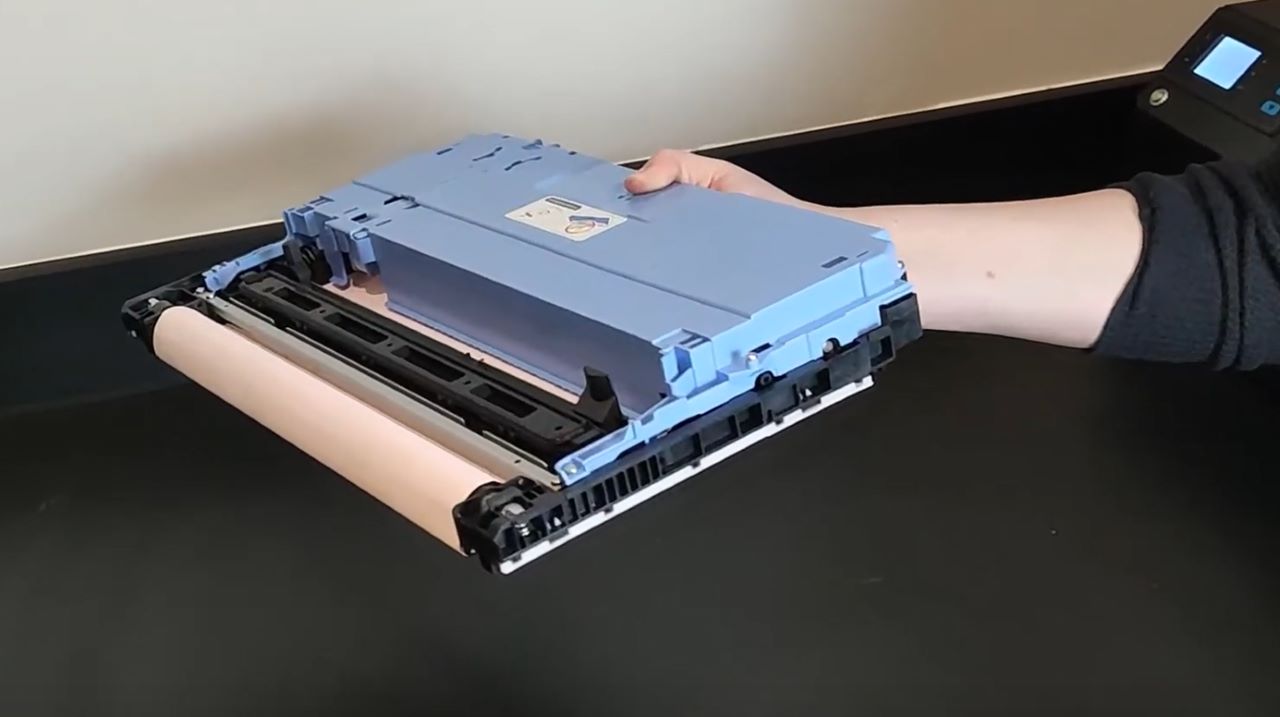

- Slide the printer forward on its table and remove all items from behind the printer. If the printer is sitting in a roll-to-roll system, you may need to move it to another table.

- Place a towel or blanket at the back of the printer to protect the printer from the impact of positioning it on its back and protect it from damage.

- Once the area is completely clear behind the printer, turn it on its back. Follow these steps and watch the instructional video below.

- Grasp the printer from the front, holding on to the protective covering, placing one hand at the printer entrance, and one at the printer exit.

- Slowly tilt the printer backward, pivoting on the two back printer feet and controlling the printer movement with your hands and forearms.

- Gently rest the printer on its back on the protective covering.

- You now have access to the underneath of the printer and the orange drive rollers.

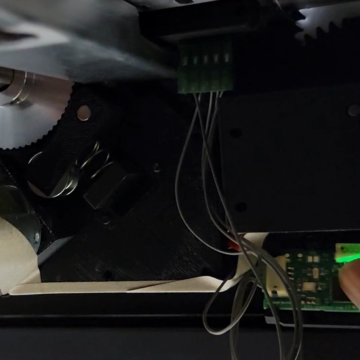

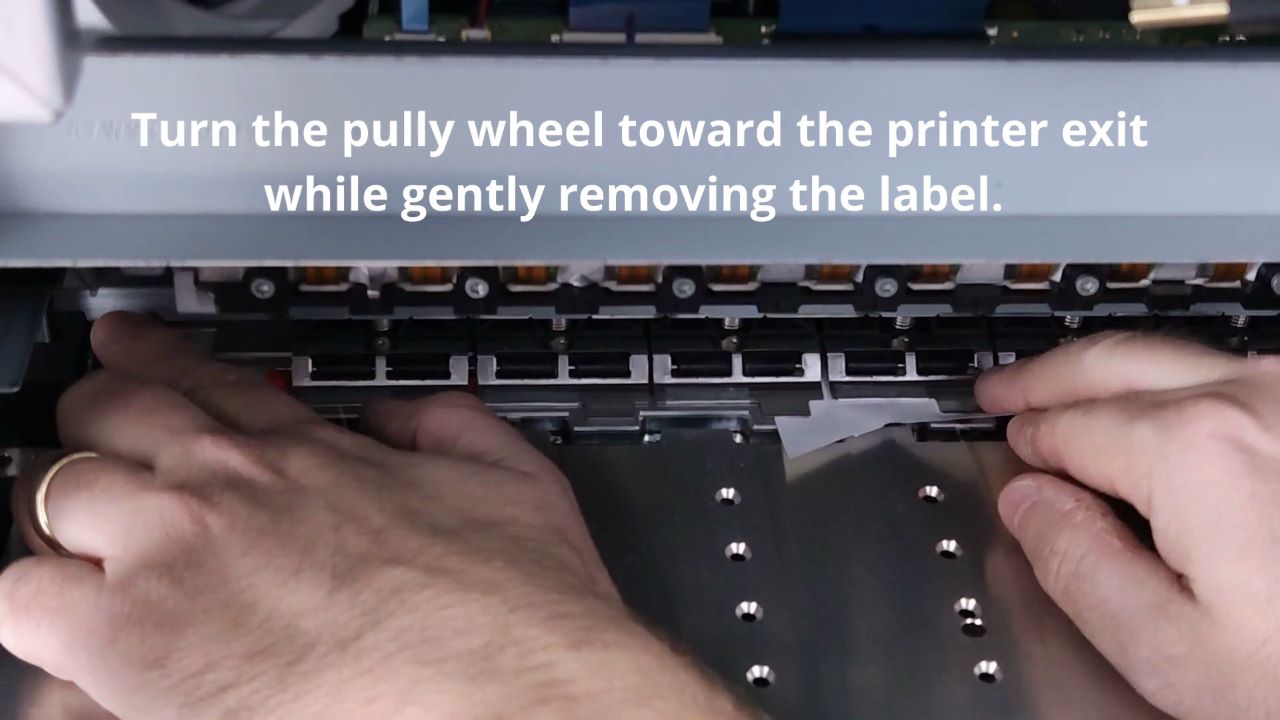

If the drive rollers do not show any signs of debris, wipe them off with a lint-free wipe and distilled water. If they do show signs of debris, usually ink and label glue, they should be gently scrubbed with a stiff sponge and isopropyl alcohol. 91% isopropyl alcohol and above is recommended for dissolving label glue. For extreme cleaning, 99% isopropyl alcohol is recommended.

Scrub the rollers gently until all discoloring and debris are removed from the rollers. Turn the rollers with your hand as you scrub to reach the full circumference of the rollers.

Once you are satisfied that the drive rollers are clean, place the printer back in its normal position. Grab the printer with both hands and gently tilt it forward until it is returned to its normal position. If needed, return the printer to the roll system. Plug in all cables, return any peripherals, and turn the printer back on.

When a printer has been placed on its back or side, ink mixing may occur. That is, the different ink colors may run through the printhead, and smudges or smears may appear on the printed page. Ink mixing is a temporary side effect of tilting the printer. Running the printhead cleaning routines or printing a few pages should alleviate any ink-mixing issues and return the printer to its normal state.